There are many technological operations involved in the workflows of manufacturing enterprises: welding, casting, CNC cutter tooling, painting, assembling and many others. The majority of them are still done by humans.

Many jobs can be automated, especially those that are monotonous and potentially harmful (this is called the ‘3 D’s of Robotics”, standing for “dull, dirty and dangerous).

They include:

Moving the parts on the assembling lines

sorting and packing of the final products

welding

feeding the materials to the assembly lines

quality control of finished products;

CNC machines maintenance;

palletizing, moving and loading work;

varnish and paint jobs;

cutting the material and polishing the surfaces.

One of the ways to automate the manufacturing is using the robotic arm manipulators, both industrial and collaborative robots (or cobots).

In 2019, the cobots made up 4.8% of all newly installed robots in the world: 355,000 traditional ones and 18,000 cobots in a year.

The diversity of possible applications for robot usage makes it possible to automate the majority of the production process and reduces the costs at various departments. Installing just two SCARA robots at the food production will bring the expenses on stuff down from 150,000 dollars per year to just 37,500. This is 25% of the initial number. This implies 3 shifts a day, 6 days a week, 48 weeks a year. The information is provided by American company TM Robotics.

The Differences Between Cobots and Industrial Robots

The industrial robots are as fast and as accurate as possible. The speed makes them dangerous for humans, so the robots are usually placed at a special location or inside a box. These two properties make up their main advantages over the cobots: impressive efficiency.

Cobots or collaborative robots are designed to be safe for humans. Their silhouettes are rounded, the speed and power are reduced, the safety features are built-in. They stop all of the operation once the sensor detects the touch.

The cobots are usually multi-purpose and versatile. They are also cheaper and pay off faster. They are easy to install and integrate, simple to program and can be a perfect fit for both large plants and small startups. They also require less power than the traditional industrial robots and take less place.

In short: the industrial robots are fast and accurate, while the cobots are safer and easier to use.

How Robots and Cobots are Used

Fields

Both industrial and collaborative robots are used for various purposes and it’s not limited to help the workers to avoid dangerous and difficult work or to reduce the expenses. The robots boost the efficiency and lower the number of defects.

According to research, 30% of the robots in the world are involved in the automotive industry, 25% – in the making of electronic components, 10% are utilized for chemical and oil-gas production, 3% are used in the food industry, 9% are used for other industries that are not the part of the list, and the rest are involved in the purposes unknown (this likely includes aerospace and military fields as well, since those are usually very secretives).

Characteristics of the Usage

Industrial robotic manipulators are programmed by the experts. It requires the work of a qualified robotic technician and the process takes some time making a robot staying idle and not operating for some time. Moving the manipulator is relatively easy compared to stationary equipment.

Cobots are easier to program. They include the learning abilities by design: if an operator moves the arm, the cobot will replicate them. This makes cobot programing much easier.

CNC Machines Maintenance

One of the most prospective work automation fields is the loading and unloading of the CNC machines. Placing a billet inside the machine, removing the processed ready-to-use parts and the change of the cutting tool are the simple tasks that don't involve having an engineering degree. They can be easily done by a robot that will do it more efficiently and cheaper.

The robots are usually used together with the CNC machines that complete the following operations:

milling,

machining,

cutting,

bending,

forming,

injection molding,

3D printing.

Usually, the robots load the billets into the CNC machines and remove the resulting processed parts. Sometimes they replace the parts of the machine: cutters, milling cutters, extruders, etc.

The Advantages of the Robotic Manipulators

Unlike the working line systems that are designed to be the part of the lines and usually just provide one function, the cobots and industrial robots are more versatile.

Multi-functional

Being multi-purpose and able to be quickly reprogrammed, the robots can be placed in any part of the manufacturing plant, have their functions changed since they are usually versatile by design and just changing the tools and the programs will do the trick. The cobots excel at it.

Convenience

It’s easy to place the robots: one cobot or the industrial robot can maintain several CNC machines at once, provided it’s placed and programmed correctly, this will save a lot of space. Cobots take even less space and don't require special places, since they can work alongside people.

Another strong point is the simplicity of repair and maintenance: the standardization of equipment requires less people to work with it. The same workers can do the maintenance in different production areas. This differs from automatic lines maintenance where there’s a different worker to maintain and repair each type of equipment. The more standardized the equipment is, the less spare parts are needed. They can be stored in the warehouses of the plants which reduce the idling time in case of malfunction.

Safety

Cobots are not dangerous to the workers, while the industrial robots are usually located in isolated places. Here’s where ‘3 D’s of Robotics” (dull, dirty and dangerous) come into play: people are replaced in the areas where they work that are dangerous or monotonous. This actually further increases the safety since both boredom and dirtiness can affect the attention of the workers and increase the risks of injuries.

Undemanding

The cases of the majority of industrial robots and cobots are IP-rated for water and dust protection. This increases the reliability and reduces the chances of failure and idling.

Efficiency

The robot doesn’t call in sick, the CNC machines maintained by it are never idle and work 24/7, three shifts, 365 days a year. This is how one robot can replace three to six workers. CNC machines that work without stopping mean higher production efficiency.

The Problems Eliminated or Partially Solved by the Robots Maintaining CNC Machines

Costs

Investing in robots pays off in intensive production with 2 shifts or more. The robots will be cheaper than the workers in the long run. This will be further discussed in the ‘Returns and Profit’ section below, where the ROI for robotics integration will be calculated.

Quality Improvements

The cobots and industrial robots work more accurately and precisely than humans. This results in higher quality of the products. This, in turn, results in less complaints, higher demand and sales.

Protecting Business Interests

Apart from reducing the risks for the workers, there’s another thing to consider: protection of business interests. The less employees there are, the easier it is to control their actions: this reduces the chances of information leaks and sabotages.

Use Cases

Automated Hardening System with Fanuc M-710iC/70

The automated metal parts hardening system was designed with the use of the industrial robot Fanuc M-710iC/70. After a billet is heated up to 910°С, the robot will place it inside a hardening press and remove the product from there and place it on the moving surface.

Safety is ensured with the help of the light sensors located inside the working chamber. They will turn the robot off if there’s a motion noticed inside the working area.

Safety: a worker doesn’t need to interact with a muffle furnace and move hot products. This results in lower risk of working injuries.

Quality: the robot is faster than a human in moving the products without it having time to cool off. This makes the product’s quality higher, reducing the risk of defects.

The payback period is estimated to be between 1.5-2 years.

Hydraulics Production

The representatives of a business that manufactures and maintains hydraulic and mechatronic equipment: mainly the hydraulic drives for other companies, asked for a solution for production line automation that would work with the billets weighing up to 10 kg on the Mazak and Haas cutters.

The capabilities of the Hanwha HCR-5 were demonstrated, since it’s one of the smallest solutions that would be perfectly suitable for such goals. But the company decided to go with the Hanwha HCR-12, a cobot that can lift up to 26 lbs. It was chosen for its lifting capacity and working area.

The device eliminates the need to keep a worker always close to the NCN machine. The employee doesn’t have to continue monotonous work of putting a billet inside the system and taking out a processed part. The company is planning to add two more of these machines soon.

The payback period is estimated to be between two to three years. After that, using the machine will be profitable for the company.

Instrument-Making Plant

The cobot called Hanwha HCR-12 was offered after considering all of the requirements such as specs and size. The device is small, it has a compact working area but can provide decent lifting capacity, reach and accuracy.

The demonstration made it clear that the cobot’s working area and reach are great for the company. They went with two Hanwha HCR-12 devices. The operators are going through training.

Another useful solution with decent payload and reach combined with a small footprint would be the Jaka Zu 12. This cobot is suitable for the situations where the usage of a compact device is required.

If everything operates without the longer idling times, the project will pay off in around 2 years and 1 month.

Instrumentation Factory

An instrumentation factory wanted to automate the processes of loading and unloading at the production line of the CNC machines.

The Hanwha HCR-5 was the solution offered to the factory. It was placed over the mobile transportation mobile robot by Omron.

This will make it possible to use one robot for maintaining and loading and unloading many machines with just one robot. The company discussed a possibility that the cobot will be placed on rails. This solution would allow for scaling up and having easier time to add more CNC machines to the system.

It doesn’t require a certain configuration of the CNC machines.

This solution would pay off in one year and 8 months with the similar number of the CNC machines.

Returns and Profitability

From our experience, the investments in automation pay off in 1-3 years (on average). After that the significant cost-savings will continue to happen. More precise payback periods can be calculated only on a case-by-case basis. This will require knowing the price of equipment and related work, as well as costs of operation and expected profit.

One robot can work almost restlessly. The machine can replace 2 to 6 workers. It will be doing so 24 hours a day, 7 days of the week, 52 weeks a year. The costs of the seek leaves, payrolls as well as insurance and personal protective equipment spent on the workers over the course of a year or two would exceed the money the company spent on buying and maintaining the robots.

Calculations

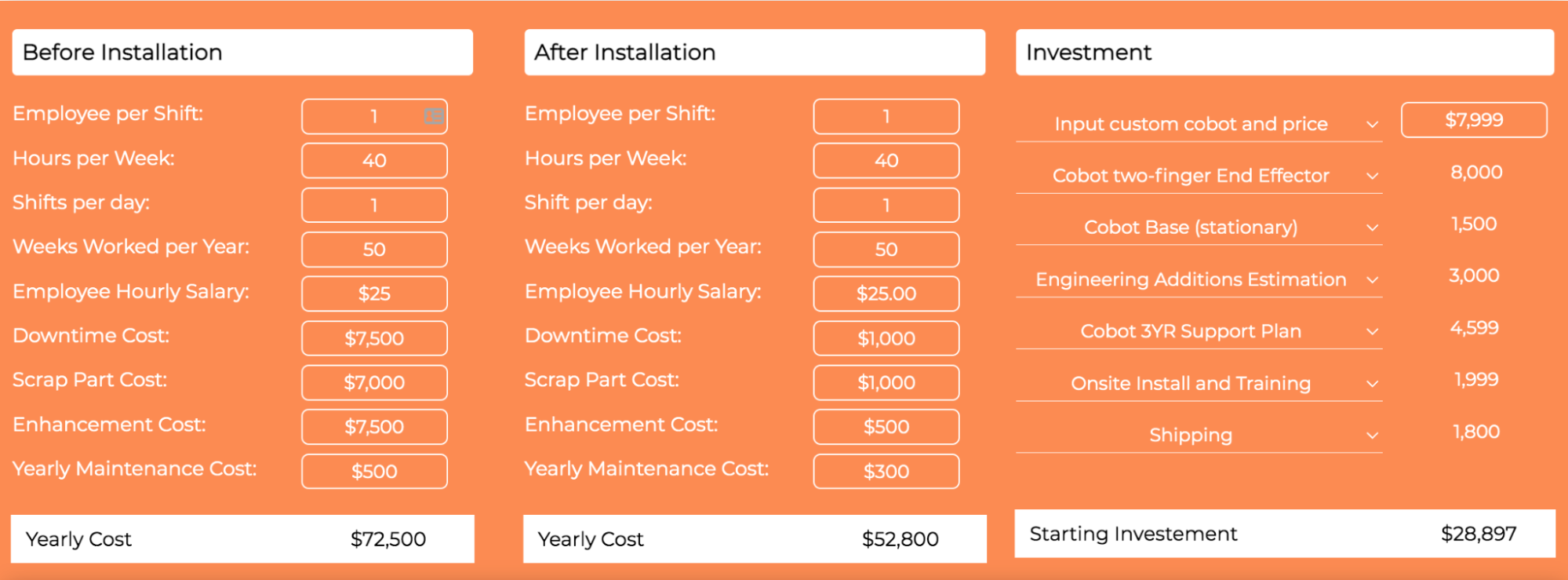

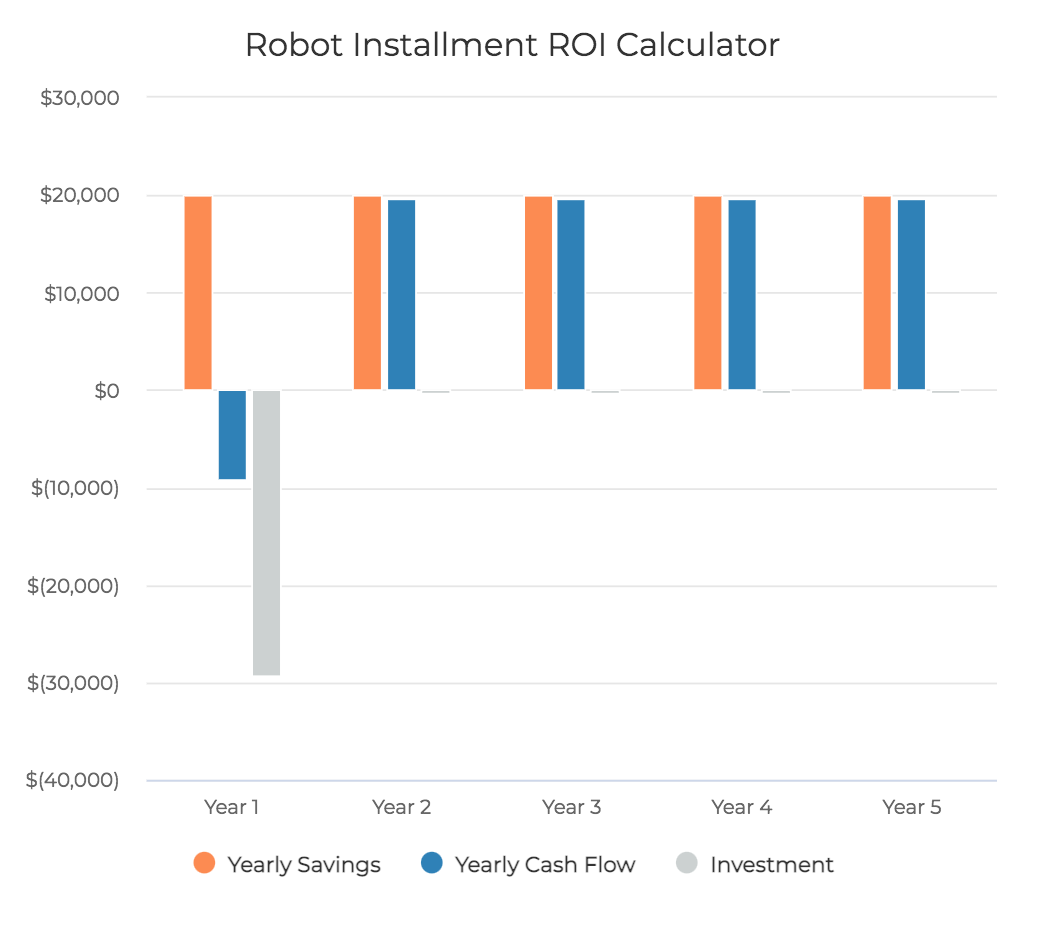

As an illustration, below you may find an example of the payback period calculation (using Cobot Nation’s ROI Calculator: https://cobotnation.com/roi-calculator/).

This version is simplified. The goal is to provide an overall idea of the differences between the costs of workers and the robots. For this example we used the uFactory xArm 6, providing a payback period of 18 months.

As is seen in the calculations, the total costs of buying a robot will be 7,999 USD, while the costs of 1 employee that would work in one shift would cost the company 50,000 USD / year. The total cost for running such an operation is $72,500 if we include other expenses.

So, from the first year onwards the business will generate yearly savings of $20,000, generating total savings of $69,603 in 5 years.

Conclusion

Integrating cobots and industrial robots at the production lines will boost the speed and efficiency of such lines. The solution will improve the quality of the products as well as cut the costs of manufacturing.

The growth was persistent and stable between 2012 and 2018. Each year there were 159,000 - 422,000 robots installed on an annual basis around the world.

The sales of the new robots plummeted in 2019. That year, there were only 373, 000 of them sold. Despite that, the number of installed and working robots continues to grow, just with a slower pace compared to the previous years. Trade wars between the US and China were the reason to slow the production.

The robots deliver profit by making the processes faster. The office costs and interaction with human resources can be significantly reduced by using robots. The robots also increase efficiency.

Manufacturing high-quality products on time will result in higher demand and sales and will boost the sales of the company and make it possible to release an even more improved product. This can be achieved by using various automation solutions.